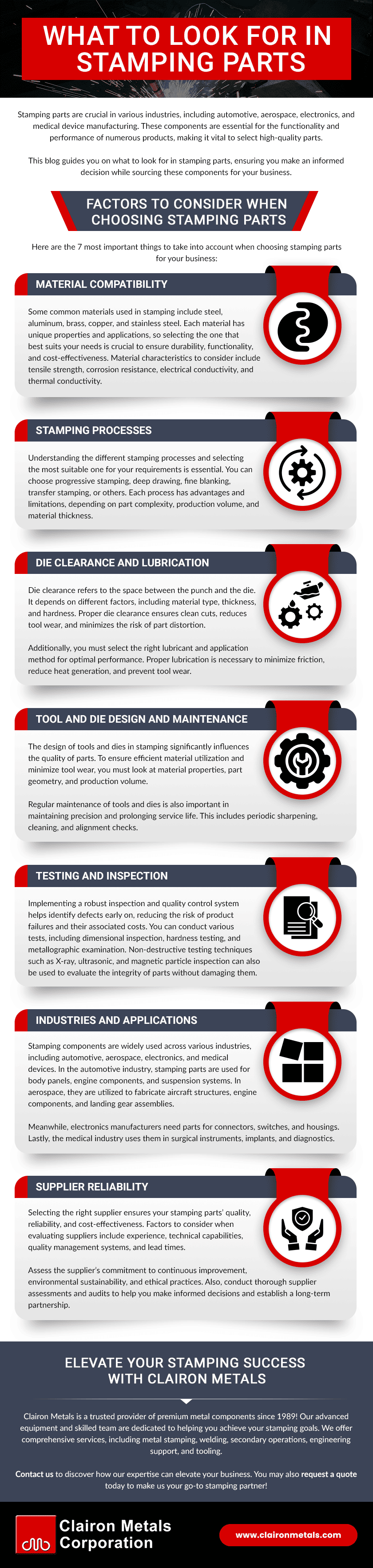

Stamping parts are crucial in various industries, including automotive, aerospace, electronics, and medical device manufacturing. These components are essential for the functionality and performance of numerous products, making it vital to select high-quality parts.

This blog guides you on what to look for in stamping parts, ensuring you make an informed decision while sourcing these components for your business.

Factors To Consider When Choosing Stamping Parts

Here are the 7 most important things to take into account when choosing stamping parts for your business:

1. Material Compatibility

Some common materials used in stamping include steel, aluminum, brass, copper, and stainless steel. Each material has unique properties and applications, so selecting the one that best suits your needs is crucial to ensure durability, functionality, and cost-effectiveness. Material characteristics to consider include tensile strength, corrosion resistance, electrical conductivity, and thermal conductivity.

2. Stamping Processes

Understanding the different stamping processes and selecting the most suitable one for your requirements is essential. You can choose progressive stamping, deep drawing, fine blanking, transfer stamping, or others. Each process has advantages and limitations, depending on part complexity, production volume, and material thickness.

3. Die Clearance and Lubrication

Die clearance refers to the space between the punch and the die. It depends on different factors, including material type, thickness, and hardness. Proper die clearance ensures clean cuts, reduces tool wear, and minimizes the risk of part distortion.

Additionally, you must select the right lubricant and application method for optimal performance. Proper lubrication is necessary to minimize friction, reduce heat generation, and prevent tool wear.

4. Tool and Die Design and Maintenance

The design of tools and dies in stamping significantly influences the quality of parts. To ensure efficient material utilization and minimize tool wear, you must look at material properties, part geometry, and production volume.

Regular maintenance of tools and dies is also important in maintaining precision and prolonging service life. This includes periodic sharpening, cleaning, and alignment checks.

5. Testing and Inspection

Implementing a robust inspection and quality control system helps identify defects early on, reducing the risk of product failures and their associated costs. You can conduct various tests, including dimensional inspection, hardness testing, and metallographic examination. Non-destructive testing techniques such as X-ray, ultrasonic, and magnetic particle inspection can also be used to evaluate the integrity of parts without damaging them.

6. Industries and Applications

Stamping components are widely used across various industries, including automotive, aerospace, electronics, and medical devices. In the automotive industry, stamping parts are used for body panels, engine components, and suspension systems. In aerospace, they are utilized to fabricate aircraft structures, engine components, and landing gear assemblies.

Meanwhile, electronics manufacturers need parts for connectors, switches, and housings. Lastly, the medical industry uses them in surgical instruments, implants, and diagnostics.

7. Supplier Reliability

Selecting the right supplier ensures your stamping parts’ quality, reliability, and cost-effectiveness. Factors to consider when evaluating suppliers include experience, technical capabilities, quality management systems, and lead times.

Assess the supplier’s commitment to continuous improvement, environmental sustainability, and ethical practices. Also, conduct thorough supplier assessments and audits to help you make informed decisions and establish a long-term partnership.

Elevate Your Stamping Success With Clairon Metals

Clairon Metals is a trusted provider of premium metal components since 1989! Our advanced equipment and skilled team are dedicated to helping you achieve your stamping goals. We offer comprehensive services, including metal stamping, welding, secondary operations, engineering support, and tooling.

Contact us to discover how our expertise can elevate your business. You may also request a quote today to make us your go-to stamping partner!