Metal Stamping Services

Metal stamping cuts and forms shaped components from steel coil using progressive dies and specialized presses and feeders. The metal stamping process is fast and efficient, making it ideal for the high-volume production of metal parts and components.

Clairon Metals is a leading metal stamper across the southeastern United States. We provide parts, blanks, and components of all complexities in medium-to-high volumes.

Metal Stamping 101

Here are some of the most common metal stamping processes of which all can be done in series in a progressive die or they can be done in steps on separate dies:

-

Punching

The punching process is used to create holes in a workpiece. The process uses a die to remove a scrap piece of material, punching a shaped hole in the workpiece. The scrap piece, known as a slug, is commonly recycled.

-

Blanking

Blanking is typically the first metal stamping step. Blanking cuts a predetermined section out of a larger piece of sheet metal for use as a more reasonably sized workpiece.

-

Embossing

Embossing creates raised or recessed shapes in sheet material by feeding sheet metal through a set of opposing male and female roller dies. One set of rollers is stationary while the other applies pressure to create the desired shape.

-

Bending

The bending process is much as it sounds. The workpiece is placed on a die and a ram pushes against it to bend the part into the desired shape.

-

Coining

Coining is a precision stamping process that creates fine details by applying a high level of force to a workpiece to press features into the metal surface. This process may only be conducted using high-tonnage presses.

-

Flanging

The flanging process bends metal at or near a 90-degree angle to create flanges—strengthened rims on the workpiece used for assembly, strength, or aesthetics. Flanging operations are typically incorporated into dies for other processes to reduce costs.

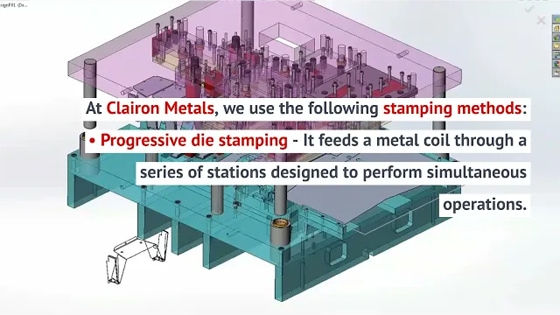

Metal Stamping Methods

At Clairon Metals, we use the following stamping methods:

- Progressive die stamping. Progressive die stamping feeds a metal coil through a series of stations designed to perform simultaneous operations. As the strip of metal moves through the process, each die station alters the metal until the final process cuts the completed part from the strip.

- Transfer die stamping. Transfer die stamping separates the workpiece from the strip and moves it between operation stations using a mechanical transfer system. This method is ideal when the presence of the metal strip may impede operations

- In Die Tapping. A rotating mechanism engages with the downstroke of the press to tap a pierced and extruded hole making and a threaded hole for use with machine screws.

Our Presses

Clairon Metals has the capacity to handle a broad range of stamping operations. We possess automated stamping presses from 35–1,100 tons, with electronic feeds to support fast-medium- and high-volume production. We can handle die sizes up to 60 inches by 144 inches and coil widths and thicknesses up to 52” and ⅜” of an inch respectively

We have 23 stamping presses to accommodate a broad range of stamping needs. The two primary types are:

- Mechanical Coil Fed

- Mechanical Single hit

Metal Stamping Ferrous & Non-Ferrous Materials

Clairon Metals works with a variety of ferrous and non-ferrous metals, including:

- Low Carbon Cold rolled and hot rolled steel

- High Strength Low Allow Coil HSLA

- High Carbon and Spring

- Prepaint Coil

- Galvanized and Galvalume

- Stainless steel 300, 400 and other series

Clairon Metals for Your Metal Stamping Needs

As a Thomas verified supplier, Clairon Metals specializes in all types of metal stamping for medium- and high-volume production runs. For more information about our metal stamping capabilities, please contact us today.