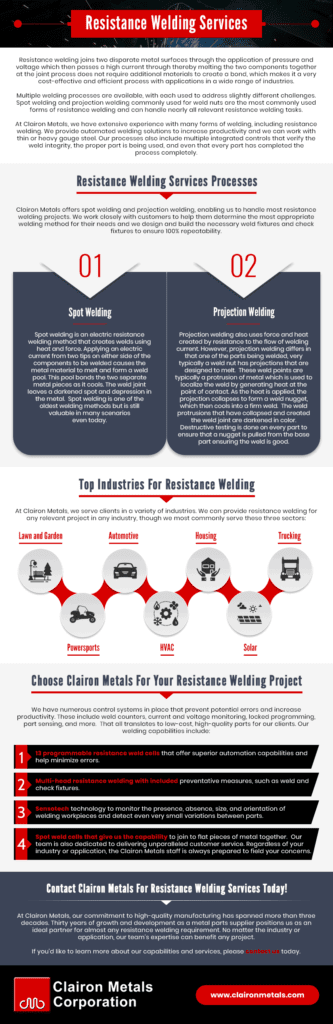

Resistance Welding Services

Resistance Welding Services

Resistance welding joins two disparate metal surfaces through the application of pressure and voltage which then passes a high current through thereby melting the two components together at the joint process does not require additional materials to create a bond, which makes it a very cost-effective and efficient process with applications in a wide range of industries.

Multiple welding processes are available, with each used to address slightly different challenges. Spot welding and projection welding commonly used for weld nuts are the most commonly used forms of resistance welding and can handle nearly all relevant resistance welding tasks.

At Clairon Metals, we have extensive experience with many forms of welding, including resistance welding. We provide automated welding solutions to increase productivity and we can work with thin or heavy gauge steel. Our processes also include multiple integrated controls that verify the weld integrity, the proper part is being used, and even that every part has completed the process completely.