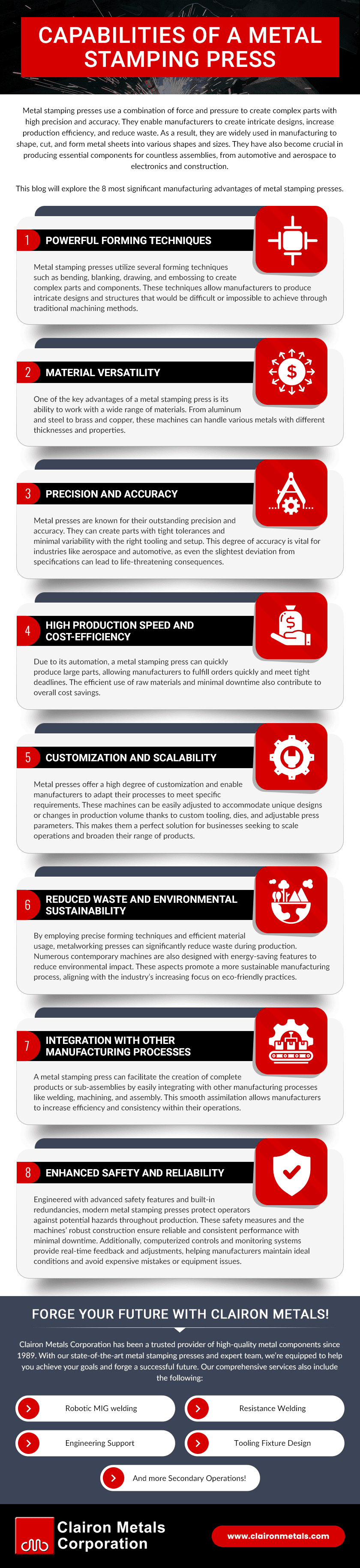

Metal stamping presses use a combination of force and pressure to create complex parts with high precision and accuracy. They enable manufacturers to create intricate designs, increase production efficiency, and reduce waste. As a result, they are widely used in manufacturing to shape, cut, and form metal sheets into various shapes and sizes. They have also become crucial in producing essential components for countless assemblies, from automotive and aerospace to electronics and construction.

This blog will explore the 8 most significant manufacturing advantages of metal stamping presses.

1. Powerful Forming Techniques

Metal stamping presses utilize several forming techniques such as bending, blanking, drawing, and embossing to create complex parts and components. These techniques allow manufacturers to produce intricate designs and structures that would be difficult or impossible to achieve through traditional machining methods.

2. Material Versatility

One of the key advantages of a metal stamping press is its ability to work with a wide range of materials. From aluminum and steel to brass and copper, these machines can handle various metals with different thicknesses and properties.

3. Precision and Accuracy

Metal presses are known for their outstanding precision and accuracy. They can create parts with tight tolerances and minimal variability with the right tooling and setup. This degree of accuracy is vital for industries like aerospace and automotive, as even the slightest deviation from specifications can lead to life-threatening consequences.

4. High Production Speed and Cost-Efficiency

Due to its automation, a metal stamping press can quickly produce large parts, allowing manufacturers to fulfill orders quickly and meet tight deadlines. The efficient use of raw materials and minimal downtime also contribute to overall cost savings.

5. Customization and Scalability

Metal presses offer a high degree of customization and enable manufacturers to adapt their processes to meet specific requirements. These machines can be easily adjusted to accommodate unique designs or changes in production volume thanks to custom tooling, dies, and adjustable press parameters. This makes them a perfect solution for businesses seeking to scale operations and broaden their range of products.

6. Reduced Waste and Environmental Sustainability

By employing precise forming techniques and efficient material usage, metalworking presses can significantly reduce waste during production. Numerous contemporary machines are also designed with energy-saving features to reduce environmental impact. These aspects promote a more sustainable manufacturing process, aligning with the industry’s increasing focus on eco-friendly practices.

7. Integration With Other Manufacturing Processes

A metal stamping press can facilitate the creation of complete products or sub-assemblies by easily integrating with other manufacturing processes like welding, machining, and assembly. This smooth assimilation allows manufacturers to increase efficiency and consistency within their operations.

8. Enhanced Safety and Reliability

Engineered with advanced safety features and built-in redundancies, modern metal stamping presses protect operators against potential hazards throughout production. These safety measures and the machines’ robust construction ensure reliable and consistent performance with minimal downtime. Additionally, computerized controls and monitoring systems provide real-time feedback and adjustments, helping manufacturers maintain ideal conditions and avoid expensive mistakes or equipment issues.

Forge Your Future With Clairon Metals!

Clairon Metals Corporation has been a trusted provider of high-quality metal components since 1989. With our state-of-the-art metal stamping presses and expert team, we’re equipped to help you achieve your goals and forge a successful future. Our comprehensive services also include the following:

- Robotic MIG welding

- Resistance welding

- Engineering support

- Tooling fixture design

- And more secondary operations!

Contact us to learn how our expertise and capabilities can contribute to your success.

Ready to take the next step? Request a quote today