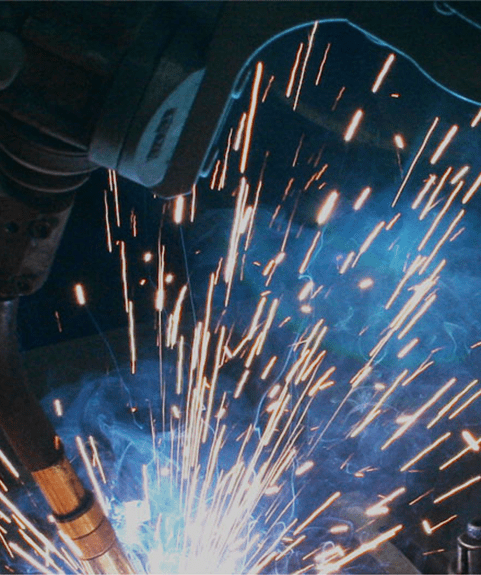

Many factories and machine shops employ Metal Inert Gas (MIG) welding, a form of Gas Metal Arc Welding (GMAW), as a method for reliably joining metal parts. The MIG welding process creates an electrical arc between a consumable wire electrode and the metal workpieces, which rapidly heats and melts the metal of the workpieces. As the filler from the consumable electrode and the melted material from the workpieces cool, they fuse together to create a single joined workpiece.

Semi-automatic robotic MIG welding has become increasingly popular for its ability to optimize precision and efficiency on production lines. This blog will discuss the robotic MIG welding process, what makes it different from other welding processes, and the industries that rely on it.

Robotic MIG Welding Process

The robotic MIG welding process uses an arm capable of three-dimensional movement. A type of wire feeder supplies the filler wire to the machine as needed to complete a weld. The arm features a high-heat electrified tip, which is responsible for melting the filler wire. Operators program the robotic welding system via a teach pendant, which integrates new programs, alters process parameters, and moves the arm.

Manual Welding vs. Robotic Welding

To understand the benefits of robotic welding over manual welding processes, there are some fundamental differences between these processes to consider.

In manual welding, humans are entirely responsible for performing the weld. Manual welding comes with certain advantages, such as flexibility and the ability to make in-process adjustments if problems arise with the weld. However, manual welding also has several disadvantages, including the risk of injury when working with high temperatures, less efficiency, slower weld speeds, and an industry-wide shortage of skilled welders.

Robotic welding involves a semi-automated process using machines to feed the consumable electrode and create the weld. The benefits of robotic welding include:

- Improved operator safety

- Consistent weld quality

- Increased output

- Minimized waste

- Reduced production costs

While robotic systems do require a high initial investment, these offer long-term benefits and cost savings that drive significant ROI over the life of the equipment.

Robotic MIG Welding vs. TIG Welding

Typically, applications with large and thick weldments will use robotic MIG welding, which is capable of producing high-quality welds at a faster rate compared to TIG welding on thicker materials. MIG welding also features reduced spatter and is usable in nearly any position. Conversely, TIG welding is often preferred for welding small or thin parts. The process isn’t as fast as MIG welding, but less maintenance and cleanup are required.

Industries That Robotic MIG Welding Is Best for

A wide range of industries use robotic MIG welding, especially those requiring reliable bonds on metal frames or structural components. Some of the industries that rely on robotic MIG welding include:

- Manufacturing. An expansive range of manufacturing sectors rely on robotic MIG welding, including Power Sports, Outdoor Power Equipment, Solar, Household Products, Appliances, HVAC, Transportation, Power Tool, and many more.

- Automotive. Automotive manufacturers use robotic MIG welding to provide reliable and consistent welds between vehicles, ensuring the same level of performance from each vehicle that comes off the production line.

- Shipping and marine. Boats, ships, and other marine equipment require an efficient welding process to produce reliable bonds on parts that will hold up in harsh marine environments.

- Construction/infrastructure. Structural steel parts and components used in buildings and infrastructure projects need strong welds to ensure long-term performance.

Clairon Metals — Your Robotic MIG Welding Experts

Robotic MIG welding provides consistent and reliable welds across production runs, offering improved efficiency, safety, and cost-effectiveness. At Clairon Metals, our robotic MIG welders can handle a broad range of projects. Our knowledgeable and skilled team of experts can provide you with top-quality precision welding solutions based on your needs. To see how we can help, please contact us or request a quote for your project today.