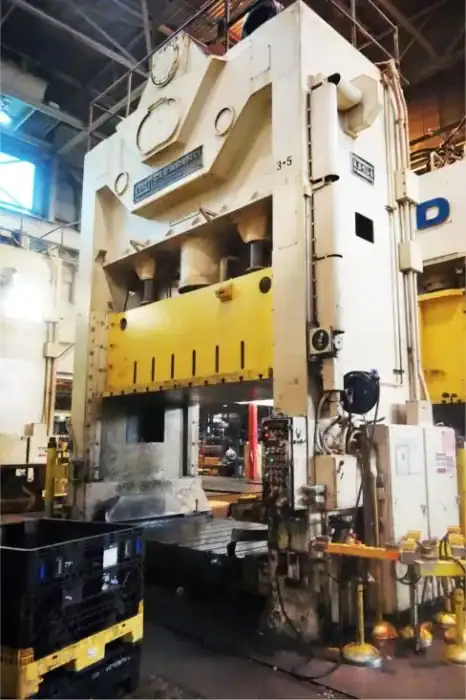

At Clairon Metals Corporation, we’re proud to offer the very best heavy metal stamping, welding and related manufacturing services to clients across a wide array of industries. We pride ourselves on always utilizing the top equipment in the industry for all of our services, and a great example is our 600-ton stamping press machine for heavy metal stamping needs. This is a press we recently installed in response to the growing demand of our clients for heavy metal stamping services. This press was installed to allow for greater capabilities and capacity under the 600 ton portion

Here are some of the reasons why high-quality equipment like stamping machines are vital for these kinds of services, plus a look at some of the specific qualities of our 600-ton stamping press machine and how it helps us create the top heavy metal stamping components in the industry.

Why Quality Equipment is Vital for Heavy Metal Stamping

There are several major reasons why quality equipment is vital for heavy metal stamping services. These include:

- Precision and Accuracy: When it comes to creating complex and intricate parts, precision and accuracy are crucial. Quality stamping machines are designed to have tight tolerances, meaning they can create highly precise and accurate components with minimal error.

- Strength and Durability: Heavy metal stamping requires the use of strong and durable equipment that can withstand the high pressures and forces involved in the process. Poor quality machines may not be able to withstand these conditions, leading to machine failures or producing subpar components.

- Speed and Efficiency: Time is money in the manufacturing industry, so having high-quality equipment that can produce parts quickly and efficiently is essential. Heavy metal stamping machines are designed to operate at high speeds and produce components with minimal error, making them a valuable asset in any production line.

- Versatile Applications: Heavy metal stamping is not limited to just one type of material. This process can be used on a variety of materials such as steel, aluminum, copper, and brass, making it a versatile choice for manufacturers. This versatility allows for the production of different types of components for various industries, including automotive, aerospace, and consumer goods.

Our 600-Ton Stamping Press Machine at Clairon Metals

At Clairon Metals, we proudly utilize a state-of-the-art USI clearing 600-ton stamping press machine for various metal stamping processes. This high-performance machine allows us to provide our clients with precision, reliability, and efficiency in producing high-quality stamped components. We are installing a feedline that can handle up to 60” wide material, allowing us to stamp larger parts and increase our production capacity.

Some specific features of this machine:

- Model: MPL2-600-180×72

- Total Capacity: 600 Tons

- Bed Size: 180” X 72”

- Ram Size: 180” X 72”

- Stroke: 16”

- Adjustment: 22”

- Shut Height: 40” max

- Speed: 20-45 SPM

Decades of Quality Service

Founded all the way back in 1989, Clairon Metals Corporation has spent decades providing clients with all their heavy metal stamping and related metal manufacturing needs. While our services have evolved with advancements in technology over the years, our commitment to quality and customer satisfaction has remained constant.

Our team of highly skilled engineers, technicians, and operators work together to provide top-notch stamped components for various industries such as automotive, aerospace, defense, and more.

Contact Us

If you’re looking for the best heavy metal stamping or related services, including further information on our 600-ton stamping press and other capabilities, please do not hesitate to get in touch with us at Clairon Metals. Our team will be happy to assist you and answer any questions you may have. We’re standing by to take your call!